Infarmight’s Modular Farms: Agriculture Anywhere, Anytime

The Global Food Challenge and Infarmight’s Answer

The world stands at a critical juncture. With a rapidly growing global population, increasing urbanization, and the undeniable impact of climate change on traditional agriculture, the challenge of securing a stable, sustainable, and localized food supply has never been more pressing. Traditional farming, with its reliance on vast tracts of land, unpredictable weather patterns, and long supply chains, is struggling to keep pace with modern demands.

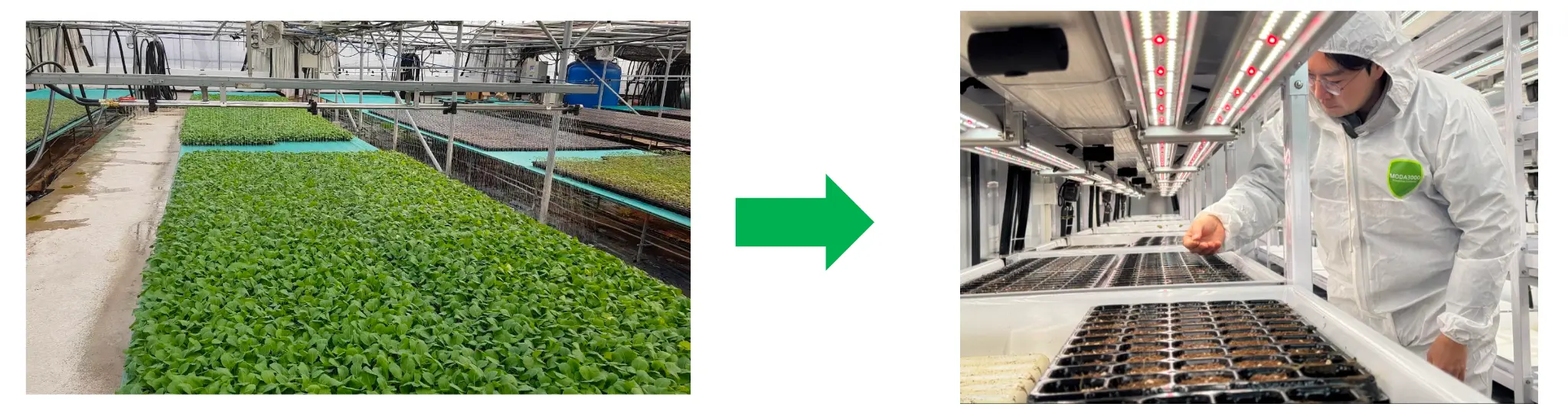

Enter Infarmight, a visionary smart farm company that is redefining the landscape of food production. Infarmight’s core innovation is a powerful, elegant solution to the food crisis: the containerized, modular farm. This concept transforms standard shipping containers into high-tech, climate-controlled vertical farms, bringing the farm directly to the consumer. It is the ultimate answer to the question of food security, offering a model for Agriculture Anywhere, Anytime.

The thesis is simple yet revolutionary: by decoupling food production from land and climate, we can create hyper-efficient, resilient, and sustainable food systems. Infarmight’s modular approach is not just an incremental improvement; it is a paradigm shift that promises to shorten the journey from farm to fork to mere meters, ensuring unparalleled freshness and nutritional value.

The Anatomy of a Modular Farm

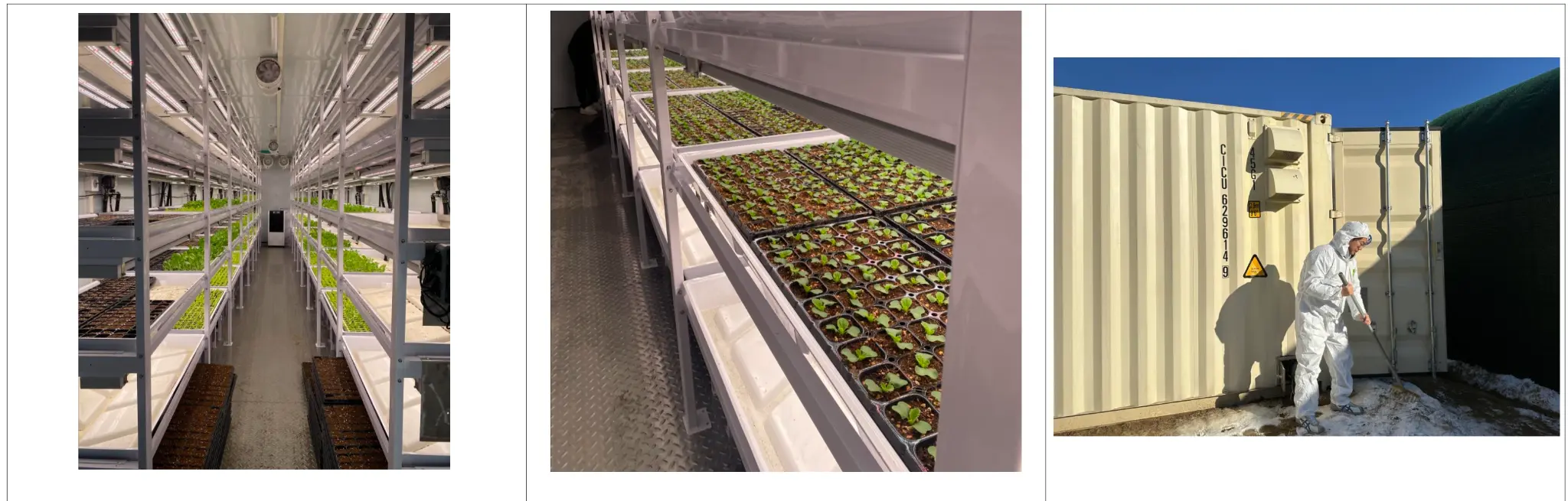

Infarmight’s modular farms are self-contained ecosystems, engineered for maximum yield and minimal resource use. They are built within robust, insulated shipping containers, which provide the perfect shell for a controlled environment. This containerization is the key to their mobility and rapid deployment. A farm can be shipped to a city center, a remote military base, or a desert community and be operational within days.

Inside the container, the space is optimized using vertical farming techniques. Instead of growing crops horizontally, plants are stacked in multiple layers, dramatically increasing the yield per square foot. The entire system operates on a closed-loop, soilless cultivation method, primarily using hydroponics or aeroponics.

Key Components of the Infarmight Module:

- Vertical Racking System: Multi-tiered shelves that maximize the growing area.

- Advanced LED Lighting: Custom-spectrum LED lights replace the sun, providing the exact wavelengths needed for optimal photosynthesis at every stage of growth. This allows for faster growth cycles and higher nutrient density.

- Climate Control Unit (HVAC): A sophisticated system that precisely regulates temperature, humidity, and air flow, creating the perfect microclimate for the specific crop being grown.

- Nutrient Delivery System: A closed-loop system that recirculates water and a precisely balanced nutrient solution directly to the plant roots, minimizing water waste.

This modular design means that a single container can produce the equivalent of several acres of traditional farmland, all while using up to 95% less water.

Technological Core: Precision Agriculture

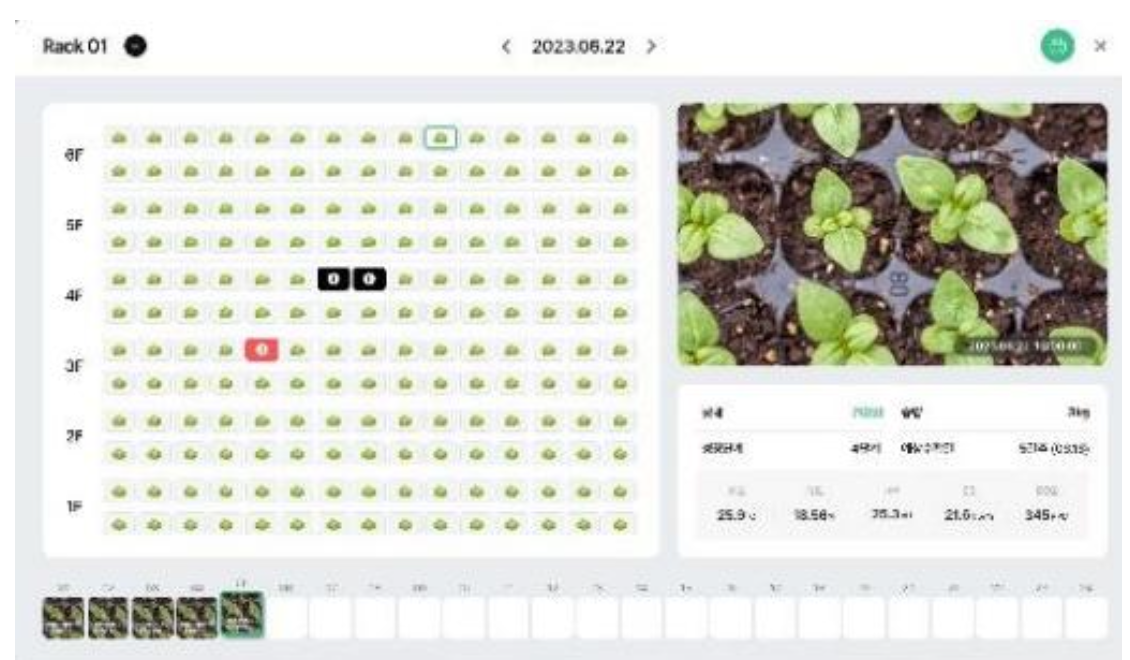

The true intelligence of the Infarmight system lies in its integration of Artificial Intelligence (AI) and the Internet of Things (IoT). These technologies transform the container from a simple box into a sophisticated, data-driven production facility.

Hundreds of sensors are deployed throughout the module, constantly monitoring every critical parameter:

- Environmental Data: Temperature, humidity, CO2 levels, and air pressure.

- Plant Health Data: Water pH, Electrical Conductivity (EC) of the nutrient solution, and even visual data from cameras to detect early signs of stress or disease.

The Role of AI in Optimization

The data collected by the IoT sensors is fed into Infarmight’s proprietary AI platform. This platform acts as the “brain” of the farm, making real-time adjustments to optimize growth:

- Automated Climate Control: The AI fine-tunes the HVAC system and LED light intensity based on the plant’s current growth stage and environmental feedback.

- Predictive Yield Modeling: By analyzing historical data and current conditions, the AI can accurately predict harvest times and yields, allowing for precise planning and inventory management.

- Nutrient Recipe Adjustment: The system automatically adjusts the nutrient solution’s composition to ensure the plants receive the perfect balance of minerals for maximum flavor and nutritional content.

This level of precision eliminates the guesswork of traditional farming. It ensures that every plant grows under ideal conditions, leading to consistent, high-quality produce year-round, regardless of external weather or season.

Economic and Environmental Benefits: The ‘Why’

The shift to Infarmight’s modular farming offers compelling advantages across both economic and environmental dimensions, making it a superior model for the future of food.

Environmental Stewardship

The environmental benefits are perhaps the most profound:

- Water Conservation: The closed-loop hydroponic system recycles water, leading to a staggering 90-95% reduction in water usage compared to field farming.

- Elimination of Pesticides: The controlled environment naturally excludes pests and diseases, making the use of harmful chemical pesticides and herbicides entirely unnecessary.

- Reduced Carbon Footprint: By placing farms in or near urban centers, Infarmight drastically cuts down on “food miles”—the distance food travels from farm to plate. This slashes transportation emissions and ensures fresher produce.

Economic Resilience

For businesses and communities, the economic case is equally strong:

- Predictable, Year-Round Yields: The controlled environment eliminates the risk associated with weather, drought, or seasonal changes, guaranteeing a stable supply and predictable revenue stream.

- Optimized Resource Use: Precision agriculture minimizes waste in water, nutrients, and energy, leading to lower operational costs over time.

- Land Independence: The modular farms can be deployed on non-arable land, such as parking lots or industrial sites, opening up new, high-value real estate for food production.

Comparative Advantage

To illustrate the stark difference, consider the following comparison:

| Feature | Traditional Field Farming | Infarmight Modular Farming |

|---|---|---|

| Water Usage | High (Rainfall dependent, evaporation loss) | Extremely Low (90-95% less, closed-loop recycling) |

| Pesticides/Herbicides | Necessary for pest and weed control | Not required (Controlled environment) |

| Yield Consistency | Highly variable (Weather, season dependent) | High (Year-round, climate-controlled) |

| Land Requirement | Extensive arable land | Minimal footprint (Non-arable land acceptable) |

| Food Miles | Long (Often thousands of miles) | Ultra-short (Meters to kilometers) |

| Nutrient Control | General soil amendments | Precision, real-time nutrient delivery |

Real-World Applications and Use Cases

The versatility of the containerized module allows Infarmight to address diverse food security and supply chain challenges across the globe.

1. Urban Food Deserts

In major metropolitan areas, Infarmight modules are being deployed to tackle “food deserts”—areas with limited access to fresh, affordable, and nutritious food. Placing a farm module in a city center or a neighborhood parking lot allows local businesses and residents to access ultra-fresh produce within hours of harvest. This localization not only boosts community health but also creates local green jobs.

2. Remote and Harsh Environments

The ability to operate independently of external climate makes Infarmight ideal for extreme locations.

- Arctic Regions: Providing fresh greens and vegetables to communities where traditional growing seasons are non-existent.

- Desert Climates: Offering a sustainable farming solution in arid regions where water scarcity is a critical issue.

- Disaster Relief: Rapidly deploying modules to provide immediate, safe food sources in areas affected by natural disasters or conflict.

3. Institutional and Corporate Integration

Major institutions are integrating Infarmight modules directly into their operations:

- Hospitals and Universities: Providing on-site, hyper-local food for cafeterias, ensuring the highest quality and lowest environmental impact.

- Tech Campuses: Offering employees a unique amenity—fresh, sustainably grown produce harvested just steps from their desks.

Scalability and the Network Effect

The true power of Infarmight’s solution is its scalability. A single container is a farm; multiple containers clustered together form a massive, distributed farming operation.

From Module to Network

The modularity allows for incremental growth. A business can start with one container and easily add more as demand increases. Crucially, all modules are connected to a central cloud-based operating system. This creates a network effect:

- Centralized Management: A single operator can monitor and manage dozens of modules across different locations from a single dashboard.

- Knowledge Sharing: The AI platform learns from every module in the network. If a specific nutrient recipe or light cycle leads to a higher yield in one location, that “knowledge” is instantly shared and applied to all other relevant modules, constantly improving the overall efficiency of the entire network.

This decentralized yet centrally managed system is incredibly resilient. If one module goes offline, the rest of the network continues to operate, ensuring a stable food supply. This is the future of farming: a distributed, intelligent, and interconnected global food system.

The Future of Food: A Vision of Decentralization

Infarmight is not just selling containers; it is selling a vision of a decentralized, resilient, and sustainable food future. The company’s roadmap includes continuous innovation in several key areas:

1. Crop Diversity Expansion

While current modules excel at leafy greens, herbs, and certain berries, Infarmight is actively researching and developing new “crop recipes” to expand the range of produce that can be grown efficiently, including root vegetables and even small fruits.

2. Enhanced Automation and Robotics

The next generation of modules will feature even greater automation, including robotic harvesting and planting systems, further reducing the need for manual labor and increasing operational efficiency.

3. Sustainable Energy Integration

Future deployments will increasingly integrate renewable energy sources, such as solar and wind power, to make the modules entirely energy self-sufficient, pushing the environmental benefits even further.

The modular farm is a testament to human ingenuity, demonstrating that the most pressing global challenges can be solved with smart, scalable technology. Infarmight is leading the charge, proving that high-quality, sustainable agriculture can indeed happen Anywhere, Anytime.

Conclusion: A New Era of Agriculture

Infarmight’s containerized, modular farms represent a pivotal moment in agricultural history. They offer a powerful combination of technological sophistication, environmental responsibility, and economic viability. By embracing this model, communities and businesses can secure their food supply, reduce their environmental footprint, and participate in a global network of intelligent, decentralized farming. The era of agriculture dictated by geography and weather is ending; the era of precision, modular, and ubiquitous farming has begun.

The future of food is not in sprawling fields, but in compact, intelligent modules, ready to be deployed wherever freshness and sustainability are needed most. Infarmight is making that future a reality, one container at a time.